The Wooden Shell Construction of Acoustic Drum Sets

Your drum’s wooden shell construction directly shapes its sonic character, with birch delivering bright projection and reduced overtones, while maple offers balanced warmth across frequencies. Ply construction dominates modern manufacturing for cost efficiency, typically using 5-9 layers, though stave shells with minimal glue provide superior resonance through angled wooden pieces. Shell thickness controls fundamental pitch, and bearing edge precision guarantees effective sound transmission. Understanding these construction methods reveals why your choice dramatically impacts performance outcomes.

We are supported by our audience. When you purchase through links on our site, we may earn an affiliate commission, at no extra cost for you. Learn more.

Notable Insights

- Ply construction dominates modern drum manufacturing, using 5-9 wood layers for efficient production and consistent durability.

- Stave shell construction uses minimal glue with angled wooden pieces, producing superior resonance and natural wood tone.

- Wood species dramatically affect sound: birch provides bright clarity, maple offers balanced warmth, oak delivers focused attack.

- Shell thickness and bearing edge contour are critical factors controlling fundamental pitch, resonance, and sound transmission.

- Hybrid configurations combine different wood species in single shells to optimize specific tonal characteristics and performance.

Types and Construction Methods of Wooden Drum Shells

When you’re looking at drum shells, you’ll find that the construction method dramatically affects both the sound and the price, and I’ve spent enough time around drum kits to know that most players don’t realize just how different these approaches can be.

Ply construction benefits include mass production efficiency, standardized quality, and lower costs, though you’ll sacrifice some resonance for durability.

Stave shell aesthetics shine through their minimal glue usage and rich resonance, created by precisely angled wooden pieces that form polygon shells before rounding.

Steam-bent and solid construction methods exist for boutique applications, but they’re labor-intensive and expensive. Solid wood drums represent the holy grail of drum shells since they’re carved from single tree trunks without any joints or glue.

Segmented shells offer complex configurations through stacked rings, while each method delivers distinct tonal characteristics based on wood grain orientation and glue content. Both stave and segmented construction provide superior tonal properties compared to standard ply shells due to their reduced glue content and optimized wood grain alignment.

Wood Species and Their Acoustic Properties

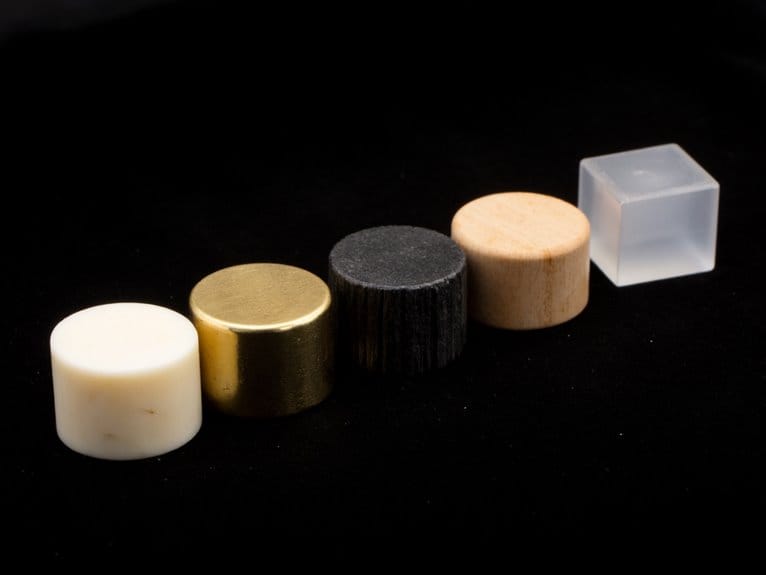

Five different wood species dominate the drum manufacturing world, and I’ve learned that each one brings such distinct acoustic characteristics to the table that choosing the wrong wood can completely undermine your sound goals.

Birch characteristics include bright, cutting projection with reduced overtones, making it my go-to recommendation for recording situations where clarity matters most.

Maple delivers balanced warmth across all frequencies, while the oak sound provides loud, focused attack with quick decay that cuts through dense mixes effortlessly.

Walnut offers naturally EQ’d warmth by reducing highs and enhancing mids, though I’ve noticed it sacrifices some projection for tonal smoothness.

Bubinga and poplar round out the specialty options, each contributing unique density-related frequency responses. Poplar’s light and resonant properties make it particularly effective for achieving smooth tonal characteristics. Mahogany delivers rich, glossy low ends with smooth mids and muted highs for vibrant projection.

Manufacturing Advantages and Sound Impact of Modern Shell Construction

Understanding the acoustic properties of different wood species only tells half the story, because the way manufacturers actually construct drum shells from these materials determines whether you’ll hear those theoretical characteristics in practice.

Modern ply construction revolutionized drum manufacturing by gluing thin wood sheets into cylinders, enabling rapid assembly and consistent results that steam-bent shells simply can’t match.

You’ll find most contemporary drums use 5 to 9 plies, balancing structural integrity with acoustic performance, while manufacturers adjust shell thickness to control fundamental pitch and resonance.

This tonal versatility allows builders to dial in specific sound profiles by combining different wood species in hybrid configurations, where dense center plies like jatoba boost attack and projection, while outer maple layers provide warmth and clarity that single-wood shells struggle to achieve. The precise bearing edge contour becomes critical for transmitting these shell characteristics effectively to the drummer’s ears. While stave construction involves trapezoid pieces aligned with the grain direction and glued end-to-end, it requires significantly more labor than ply construction despite producing enhanced natural wood tone.

On a final note

You’ve now got the foundation to make informed decisions about wooden drum shells, whether you’re upgrading your current kit or building from scratch. I’ve found that understanding construction methods, wood species characteristics, and manufacturing techniques helps drummers choose shells that complement their playing style and musical goals. Remember, there’s no perfect shell material—just the right one for your sound preferences, budget constraints, and performance requirements.