Understanding Phantom Power Delivery Through Cables

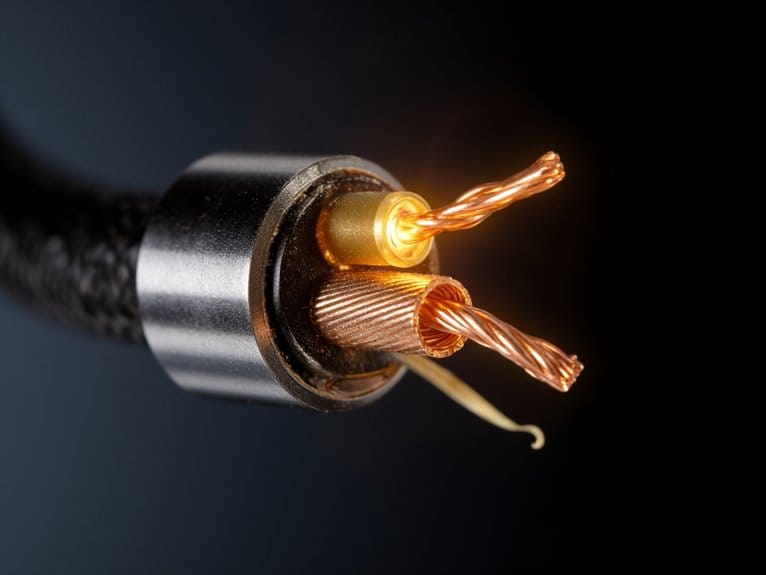

When you connect a condenser microphone, phantom power delivers 48V DC through your XLR cable’s pins 2 and 3, each carrying identical positive voltage through 6.81kΩ resistors while pin 1 provides the return path. This clever design lets your audio signal and power share the same conductors without interference, thanks to balanced transmission and common mode rejection that keeps noise at bay. Most professional condensers need this 48V supply to operate their internal electronics, though you’ll want to verify compatibility since vintage ribbon mics can suffer damage from phantom power if you’re not careful about your connections.

We are supported by our audience. When you purchase through links on our site, we may earn an affiliate commission, at no extra cost for you. Learn more.

Notable Insights

- Phantom power delivers 48V DC through XLR pins 2 and 3 via 6.81kΩ resistors in balanced cables.

- Audio signals remain isolated from power delivery through differential signaling and common mode rejection techniques.

- Cable quality directly affects phantom power delivery efficiency and overall microphone performance during recording sessions.

- Voltage drops over longer cable runs can impair microphone operation and introduce unwanted noise artifacts.

- Twisted pair cable configuration maintains clean audio transmission despite sharing conductors for both power and signal.

The Fundamentals of DC Voltage Supply in Audio Cables

The invisible workhorse of professional audio, phantom power represents one of those brilliant engineering solutions that most people never think about until something goes wrong.

When you’re dealing with condenser microphones, you’ll encounter this 48V DC supply that travels through your XLR cables alongside audio signals, and honestly, it’s pretty clever engineering.

The DC voltage flows equally through both signal conductors, which maintains excellent signal integrity while powering your microphones without introducing noise or interference. This unidirectional flow characteristic of DC power ensures consistent and reliable microphone operation without the voltage reversals that would occur with AC power.

Professional DC cable specifications require proper shielding and balanced design to guarantee this phantom power doesn’t mess with your audio quality, and the current limitation to about 10mA protects your expensive gear from damage. If phantom power fails to function properly, checking your browser settings or audio interface configuration can help identify whether software conflicts are preventing proper power delivery to your microphones.

Technical Mechanics of Balanced Cable Power Transmission

Behind that simple DC voltage supply lies a surprisingly sophisticated electrical dance that’s happening inside your balanced cables, and honestly, understanding how it all works together makes you appreciate just how elegant this whole system really is.

Your XLR cable’s pins 2 and 3 each carry identical +48V DC through those 6.81kΩ resistors, while simultaneously transmitting differential audio signals that remain completely isolated from the power delivery.

The conductor resistance actually helps maintain stable current flow, and because both signal lines carry the same voltage referenced to ground, you get exceptional noise attenuation through common mode rejection.

What’s brilliant here is that the DC power becomes invisible to non-phantom devices, while the twisted pair configuration guarantees your audio stays clean despite sharing the same conductors with power. This current limitation of 10 mA per microphone ensures device compatibility while preventing potential damage to connected equipment.

Industry Voltage Standards and Equipment Variations

Five different phantom power voltages have emerged as industry standards over the decades, and while you might assume they’re all interchangeable, each one serves specific purposes that can make or break your recording setup.

The AES defines five phantom voltage specifications—P12L, P12, P24, P48, and P48H—though 48V dominates professional applications due to its robust power delivery capabilities.

You’ll find that mixing consoles typically offer channel-specific phantom power switches, while smaller mixers often provide global switching for all inputs simultaneously.

Instrument amplifiers rarely supply phantom power, requiring external supplies for condenser microphones.

Digital microphones following AES42 standards use 10V with higher current capacity, employing specialized XLD connectors to prevent compatibility issues with traditional analog equipment and ensuring proper voltage specifications throughout your signal chain.

Microphone Compatibility and Safety Considerations

Understanding which microphones work safely with phantom power becomes considerably more complex when you’re dealing with different microphone technologies, each responding differently to that 48-volt DC supply coursing through your XLR cables.

| Microphone Type | Phantom Power Compatibility | Safety Notes |

|---|---|---|

| Condenser | Required for operation | Needs 24V-48V, 10mA minimum |

| Dynamic | Safe but unnecessary | DC voltage cancels out naturally |

| Ribbon (vintage) | Potentially dangerous | Can damage internal components |

| Ribbon (modern) | Generally safe | Check manufacturer specifications |

| Specialized mics | Varies by model | May require P12L or SP48 variants |

Different microphone types have vastly different power requirements, and I’ve learned that assuming compatibility can cost you expensive equipment repairs when voltage gets applied incorrectly through faulty cables.

Professional Implementation and Setup Procedures

When you’re setting up phantom power in professional environments, I’ve found that proper implementation turns what should be a straightforward process into something that requires methodical attention to detail, careful sequencing, and a healthy respect for the 48 volts coursing through your XLR connections.

I always start with preamp gains down and phantom power off, connecting microphones before activating power to prevent damaging transient pops.

Cable maintenance becomes essential here—damaged conductors can completely disrupt phantom power delivery, so I inspect XLR cables regularly for signal integrity.

Label your channels clearly, especially in complex setups where multiple devices require phantom power.

Train your staff on proper procedures, because I’ve seen expensive equipment damaged from simple connection mistakes that could’ve been easily avoided.

Historical Development and Technological Evolution

You’ll find it fascinating that phantom power‘s journey from telephone lines to your studio microphones spans over a century, beginning with 1919 telecommunications systems that needed efficient power delivery without additional wiring.

The evolution from bulky external power supplies requiring multi-pin cables to today’s streamlined +48V standard through XLR connections represents one of audio engineering‘s most practical innovations, though I’d argue the path wasn’t always obvious to early adopters.

Understanding how we moved from Schoeps’ obsolete 9V system in 1964 to Neumann’s game-changing +48V implementation reveals why modern phantom power works so reliably, while also explaining the sometimes puzzling compatibility issues you might encounter with vintage equipment.

Pre-Phantom Power Solutions

Before phantom power revolutionized professional audio in the mid-1960s, microphone powering was frankly a logistical nightmare that I wouldn’t wish on any sound engineer.

You’d be dealing with bulky external power supplies that required separate cables, wall outlets, and enough rack space to house a small computer.

Those early microphone designs, particularly vacuum tube condensers from the 1920s, demanded external units for both filament heating and capsule polarization, making portable recording sessions nearly impossible.

Even early transistorized mics often relied on cumbersome power boxes positioned close to the microphone itself.

This legacy equipment created cable management headaches that turned simple recording setups into complex engineering puzzles, limiting creativity and mobility in professional environments.

Industry Standardization Process

As innovative as phantom power seemed when it emerged from telephone technology in 1919, the audio industry didn’t exactly rush to embrace standardized implementation until the chaos of incompatible power schemes became too expensive to ignore. When Neumann finally pioneered the formal P48 standard in the 1960s, establishing 48V delivery through balanced XLR connections, the DIN 45596 specification followed, limiting current to just 2 mA per microphone—adequate for early condensers but woefully insufficient for today’s complex circuitry.

| Standard Era | Current Capability |

|---|---|

| DIN 45596 (1960s) | 2 mA maximum |

| IEC 61938 (Modern) | 10 mA maximum |

| Legacy Equipment | 1-2 mA typical |

Despite phantom power advantages like simplified cabling, current limitations still plague budget equipment, creating compatibility nightmares you’ll face with newer microphones requiring robust power delivery.

Modern Implementation Advances

While those early standardization efforts laid important groundwork, I’ve watched phantom power technology evolve dramatically since the 1960s, transforming from simple DC delivery circuits into sophisticated power management systems that can handle today’s demanding microphone electronics.

Modern designs now incorporate isolated, regulated supplies that dramatically reduce noise and prevent ground loops, while solid-state components have replaced bulky transformers in many applications.

You’ll find that contemporary phantom power circuits can deliver clean, stable voltage to complex active electronics within microphones, supporting everything from multi-capsule condensers to advanced digital processing units.

These improvements have expanded phantom power’s applications beyond basic microphones to active direct boxes, in-line processors, and other professional audio devices requiring reliable DC power delivery through balanced cables.

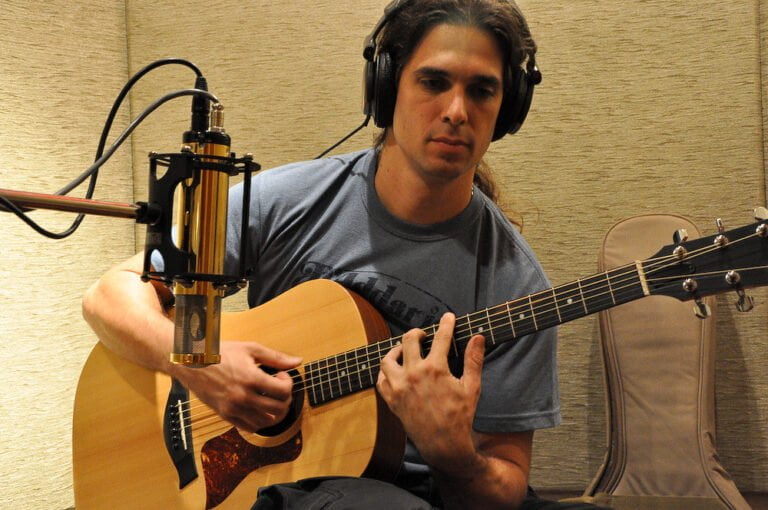

Common Applications in Studio and Live Sound Environments

I’ve spent countless hours in both studio control rooms and bustling live venues, and phantom power consistently proves itself as one of those behind-the-scenes workhorses that makes professional audio possible.

You’ll find this technology essential whenever condenser microphones enter your signal chain, whether you’re recording delicate string sections or capturing drum overheads in chaotic concert environments.

The applications span virtually every professional scenario:

- Vocal condensers requiring +48V for their internal preamps and diaphragm polarization systems

- Overhead drum microphones delivering crisp cymbal detail in both controlled studio sessions and energetic live performances

- Ambient room mics capturing natural reverb and spatial characteristics during recording projects

- Direct console integration eliminating bulky external power supplies that clutter your workspace

Quality cable types and careful noise considerations become critical factors, especially during longer runs where voltage drops can compromise your microphone’s performance and introduce unwanted artifacts.

Frequently Asked Questions

Can I Use Phantom Power With Wireless Microphone Transmitters Safely?

Yes, you can safely use phantom power with wireless transmitters if you verify wireless system compatibility and check your microphone power requirements. Most modern transmitters let you toggle phantom power on or off.

Does Cable Length Affect Phantom Power Voltage Delivery to Microphones?

Yes, cable length greatly affects phantom power delivery. Longer cables increase cable impedance and resistance, causing voltage drop from the nominal 48V. You’ll notice reduced microphone performance with cables exceeding 50 feet without compensation.

Why Do Some Audio Interfaces Have Separate Phantom Power per Channel?

You’ll find separate phantom power per channel enables phantom power distribution control and channel independence, letting you power only condenser mics while protecting ribbon mics from damage in mixed setups.

Can Phantom Power Damage My Audio Interface if Microphone Shorts Out?

Mic shorting risks can strain your interface’s power supply and potentially damage circuitry. Most interfaces include protection, but repeated shorts may cause harm. Audio interface safety improves when you disconnect faulty mics immediately.

Do Expensive XLR Cables Provide Better Phantom Power Delivery Than Cheap Ones?

Expensive XLR cables don’t provide better phantom power delivery than cheap ones. You’ll get the same +48V regardless of cable materials or minor impedance differences, as long as the cable’s properly wired and meets XLR standards.

On a final note

Now that you’ve explored phantom power‘s technical foundations, from the 48-volt standard flowing through balanced XLR cables to modern microphone compatibility requirements, you’re equipped to implement these systems confidently in your audio setups. Whether you’re configuring studio condensers or managing live sound applications, understanding voltage delivery mechanics, safety protocols, and equipment variations guarantees you’ll avoid costly mistakes while maximizing your gear’s performance potential in professional environments.