Understanding Cable Shielding and Interference Protection

You’ll find that cable shielding uses five primary technologies—foil, braided, spiral, tape, and composite solutions—to block electromagnetic interference that causes audio crackling, network drops, and video flickering. Foil shields provide 100% coverage for high frequencies, while braided copper offers 40-96% coverage with superior durability below 100 MHz. Proper grounding to low-impedance paths proves essential, as routing inner shields to system ground improves performance by 4 dB compared to floating configurations, and there’s much more to take into account when selecting ideal protection.

We are supported by our audience. When you purchase through links on our site, we may earn an affiliate commission, at no extra cost for you. Learn more.

Notable Insights

- Cable shielding uses foil, braided, spiral, tape, and composite technologies to protect against electromagnetic interference with varying coverage levels.

- Shield effectiveness depends on frequency range, with low-frequency performance relying on resistance and high-frequency requiring complete coverage.

- Proper grounding connections to low-impedance paths are crucial, improving shielding effectiveness by up to 4 dB compared to floating configurations.

- Material selection impacts performance, with copper offering excellent conductivity, aluminum providing cost-effectiveness, and nanomaterial coatings enhancing electromagnetic absorption.

- Implementation requires frequency-appropriate techniques: single-point grounding for low frequencies, multi-point for high frequencies, plus proper component spacing.

Types of Cable Shielding Technologies

Five primary shielding technologies dominate the cable protection landscape, and I’ve spent enough time troubleshooting interference issues to appreciate how each one tackles electromagnetic problems differently.

You’ll encounter foil shielding offering 100% coverage with aluminum-polyester construction, though it requires careful installation techniques due to limited flex life.

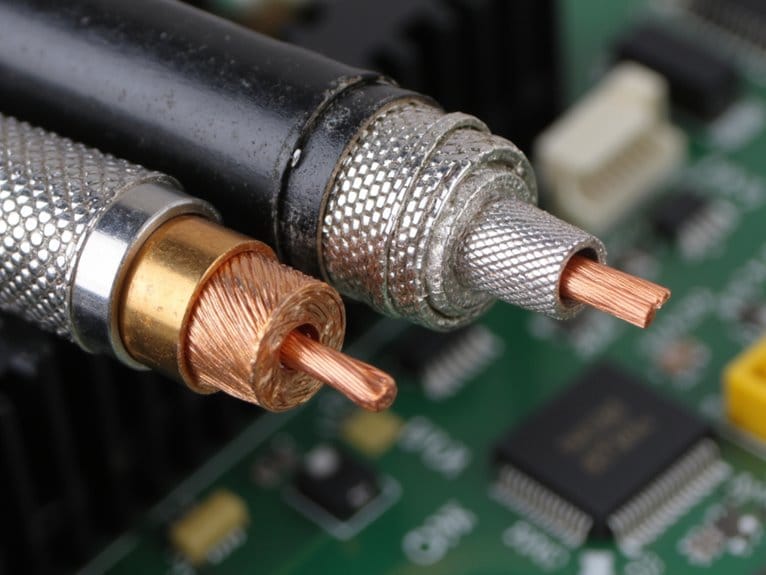

Braided shields, woven from copper strands, provide 40-96% coverage with superior durability but higher costs.

Copper-woven braided shields deliver exceptional durability and wide coverage range, though premium materials drive up implementation costs significantly.

Spiral shielding wraps copper helically for 95% coverage, excelling in flexible applications.

Tape shielding mirrors foil’s near-complete protection while remaining lightweight.

Finally, composite solutions combine multiple technologies—like foil-plus-braid configurations—delivering enhanced performance for demanding emission standards compliance. These shielding technologies find essential applications in both communication cables and medium to high voltage power installations.

Each technology serves specific applications where coverage, flexibility, cost, and mechanical strength requirements vary markedly. Proper grounding connections to low-impedance paths remain critical for maximizing the effectiveness of any shielding technology.

Shielding Materials and Construction Methods

The foundation of effective cable shielding lies in understanding how different materials interact with electromagnetic fields, and I’ve learned through countless installations that material choice can make or break your interference mitigation strategy.

When comparing materials, copper leads with excellent conductivity, while aluminum foil offers cost-effective coverage at lighter weights. Silver-coated options enhance performance in specialized applications, though they’ll hit your budget harder than standard alternatives. Modern nanomaterial coatings applied to cable surfaces significantly enhance electromagnetic absorption capabilities beyond traditional metallic shields.

Construction techniques vary considerably between braided and foil shields, each serving distinct purposes in your electromagnetic protection arsenal.

Braided copper provides 40-96% coverage with superior flexibility, making termination straightforward but expensive. Foil shields achieve 100% coverage using aluminum laminated to plastic backing, requiring drain wires for proper grounding.

Hybrid approaches combine both methods, leveraging foil’s complete coverage with braid’s mechanical durability for thorough protection.

Frequency Response and Performance Characteristics

When you’re selecting cable shielding, understanding how different frequencies affect your shield’s performance becomes essential, since what works brilliantly at low frequencies might fail miserably when you push into higher ranges.

I’ve learned through countless measurements that your shield’s effectiveness changes dramatically across the frequency spectrum, with low-frequency performance relying heavily on shield resistance while high-frequency protection demands nearly perfect coverage to prevent electromagnetic interference from sneaking through tiny gaps.

You’ll discover that the physics behind shielding shifts considerably as frequencies climb above 100 MHz, where wavelength relationships, phase shifts, and coverage percentages determine whether your carefully chosen cable becomes a reliable signal pathway or an unintentional antenna broadcasting interference.

Low Frequency Shield Performance

Four key factors determine how well your cable shield performs at low frequencies, and I’ll admit, understanding this relationship isn’t as straightforward as manufacturers sometimes make it seem. Transfer impedance effects markedly impact protection below 100 kHz, where lower values indicate superior shielding. Your measurement approach matters too, since traditional scattering parameters often fail at these frequencies, making gain-based methods more reliable for accurate shielding effectiveness measurement.

| Shield Type | Low Frequency Performance | Transfer Impedance |

|---|---|---|

| Braided | Excellent below 1 MHz | Very Low |

| Solid | Good, improves with thickness | Low |

| Foil | Poor, high transfer impedance | High |

| Metal Tape | Good initially, degrades mid-band | Low to Moderate |

Proper grounding becomes critical here, where routing your inner shield to system ground can improve performance by 4 dB compared to floating configurations.

High Frequency Protection Methods

Frequency response characteristics tell a completely different story when you’re dealing with high-frequency interference, where shield materials and construction methods that worked beautifully at low frequencies suddenly show their limitations.

You’ll discover that shielding effectiveness becomes increasingly dependent on coverage percentage, material conductivity, and grounding quality as frequencies climb above 15 KHz.

Modern high-frequency protection relies on sophisticated approaches:

- Foil shields providing 100% coverage with aluminum/polyester construction for lightweight, low-resistance protection

- MultiShield designs combining foil and braid layers for superior frequency absorption across wide bandwidths

- Carbon nanotube coatings offering enhanced conductivity and mechanical strength for efficient electromagnetic dissipation

- Copper tape wrapping around cores with proper grounding for thorough external field protection

Smart grounding prevents signal leakage while optimizing performance across the entire spectrum.

Shielded Cable Categories and Industrial Applications

When you’re selecting cables for your industrial network, you’ll need to understand that different shield configurations offer varying levels of electromagnetic interference protection, from basic foil wrapping to complex multi-layer systems.

Your environment’s noise characteristics, whether it’s a quiet office or a factory floor filled with arc welders and variable frequency drives, will dictate which shielding category you should choose.

I’ve found that matching the right shield type to your specific application requirements can mean the difference between reliable data transmission and costly network failures in electrically harsh conditions.

Cable Shield Classifications

The intricate world of cable shield classifications might seem overwhelming at first glance, but I’ve found that understanding these designations becomes much clearer when you break down the systematic approach behind them.

The ISO/IEC 11801 standards provide a logical naming convention that tells you exactly what cable shielding configuration you’re working with, and honestly, it’s quite elegant once you grasp the pattern.

Here’s how the classification system works for interference mitigation:

- U/UTP – No shielding whatsoever, relying solely on twisted pairs

- F/UTP – Foil around individual pairs only, providing targeted protection

- S/FTP – Braided overall shield with foil around each pair

- SF/STP – Combined foil and braid shielding for maximum interference protection

Industrial Environment Requirements

While office environments might seem challenging enough for cable installations, industrial settings present an entirely different beast that’ll test both your cable selection skills and your understanding of electromagnetic interference protection.

You’re dealing with M3I3C3E3 severity levels here, where factory floors assault cables with relentless vibration, chemical exposure, and electromagnetic chaos from heavy machinery.

Industrial safety demands you consider every environmental factor—dust ingress, temperature extremes, and corrosive atmospheres that’ll destroy inadequately protected cables faster than you’d expect.

Environmental conditions in these spaces require robust shielding configurations like SF/FTP cables, combining braided and foil shields to maintain signal integrity amid the electrical noise.

Your cable selection directly impacts automation accuracy, process control reliability, and overall operational safety in these demanding industrial environments.

Application-Specific Shield Selection

Understanding these harsh industrial realities means you’ll need to match specific shield types to your application’s unique challenges, and I’ve learned through years of troubleshooting failed installations that one-size-fits-all approaches simply don’t work in specialized environments.

Effective cable shield optimization requires analyzing your specific application challenges against each environment’s EMI profile, mechanical stress levels, and performance requirements.

Consider these critical application matches I’ve validated in the field:

- Medical imaging systems demand foil shielding’s 100% coverage to prevent interference with MRI and CT equipment.

- Military aerospace applications require combination shielding for extreme mechanical stress and EMI protection.

- Electric vehicle systems need robust combination shields protecting battery management and driver-assistance electronics.

- Telecommunications infrastructure benefits from foil or combination shielding ensuring stable broadband transmission under continuous data loads.

Core Functions and Operational Benefits

When you’re dealing with cable installations, I’ve found that understanding the core functions of shielding can make the difference between a system that works flawlessly and one that’s plagued with interference issues.

Cable shielding serves as your primary defense against electromagnetic interference (EMI) and radio frequency interference (RFI), ensuring signal retention even in environments packed with electronic devices. The shield acts like a protective barrier, absorbing and deflecting external interference while simultaneously preventing your cable from emitting its own electromagnetic radiation that could disrupt nearby equipment.

What I’ve observed consistently is that proper shielding delivers crosstalk reduction between bundled cables, maintaining signal clarity when multiple cables run together.

The shield effectively grounds absorbed interference, directing it safely away from your signal path and preserving data integrity throughout transmission.

Selection Criteria for Optimal Shielding Solutions

Selecting the right shielding solution isn’t just about grabbing the most expensive option and hoping for the best—I’ve learned that matching specific material properties to your application’s unique demands determines whether you’ll achieve ideal performance or end up with an overengineered, costly nightmare.

Shield effectiveness depends on several critical factors that require careful material comparison:

- Frequency range compatibility – braided shields excel below 100 MHz, while foil provides superior high-frequency protection

- Environmental durability – stainless steel withstands harsh conditions, copper offers excellent conductivity, aluminum balances cost and weight

- Flexibility requirements – braids handle dynamic applications better than rigid foil shields

- Budget constraints – aluminum foil costs less but sacrifices long-term durability compared to premium copper solutions

Implementation Strategies for Maximum EMI Protection

Four fundamental pillars—grounding optimization, strategic shielding deployment, intelligent filtering, and thoughtful component placement—form the backbone of any successful EMI protection strategy.

I’ve discovered that implementing these techniques in coordinated layers rather than isolated patches delivers exponentially better results. You’ll want to start with single-point grounding for low-frequency applications, then shift to multi-point systems when dealing with high-frequency interference.

Your shielding techniques should encompass both localized metallic enclosures around sensitive components and complete Faraday cage implementations for entire systems.

I’ve found that combining EMI filters at critical interfaces with strategically placed decoupling capacitors creates multiple defense barriers.

Effective EMI management requires maintaining adequate spacing between high-speed and analog circuits while ensuring all shields connect firmly to ground through short, direct paths.

Frequently Asked Questions

How Do I Properly Ground Shielded Cables to Maximize Interference Protection?

You’ll maximize interference protection by using proper grounding techniques like connecting shields at both ends for low-impedance paths. Choose appropriate shielding types—braided shields outperform foil in high-noise environments requiring ideal protection.

Can Damaged Cable Shielding Be Repaired or Must the Entire Cable Be Replaced?

You can attempt minor cable repair using conductive tapes or soldered braids, but shielding integrity rarely returns to original specifications. For critical applications or extensive damage, you’ll need complete cable replacement.

Do Shielded Cables Require Special Storage Conditions to Prevent Shield Degradation?

Yes, you’ll need controlled storage temperature and humidity control for shielded cables. Store them indoors, seal cable ends, avoid moisture exposure, and maintain stable temperatures to prevent shield corrosion and degradation.

What Testing Methods Verify Shielding Effectiveness After Cable Installation?

You’ll conduct shielding tests using network analyzers with triaxial setups to measure transfer impedance and RF leakage. These effectiveness measurements verify shield integrity under physical stress, detecting degradation down to -100 dB levels.

How Does Cable Length Affect Shielding Performance and Grounding Requirements?

As cable length increases, you’ll notice shielding effectiveness decreases considerably, especially when approaching signal wavelength fractions. You’ll need more sophisticated grounding strategies for longer cables to prevent resonance and maintain proper EMI protection throughout the installation.

On a final note

You’ve now got the essential knowledge to tackle cable shielding decisions with confidence. Whether you’re dealing with braided copper, foil barriers, or spiral-wound configurations, you’ll understand how construction methods, frequency responses, and environmental factors interact. Don’t overthink the selection process—match your shielding requirements to actual interference threats, consider installation constraints, and remember that proper grounding techniques often matter more than expensive premium materials.